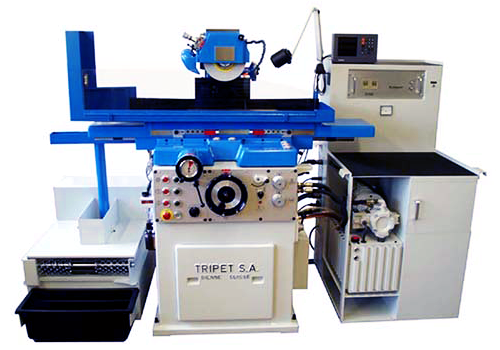

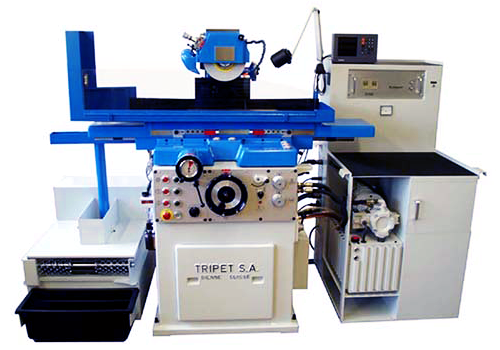

TRIPET MHPE 500

Hydraulic surface grinding machine of high precision 500x200mm

(made by LKS Grinding GmbH)

The MHPE 500 has been designed for surface and form grinding operations of highest demands as to precision, surface quality and efficiency. MHPE 500 is a machine of practical and compact design, of high rigidity. Operation is extremely simple and handy. It is the ideal machine for the tool industry, the instrument industry, the mechanical and precision industry and for machining of single components up to grinding of large batches.